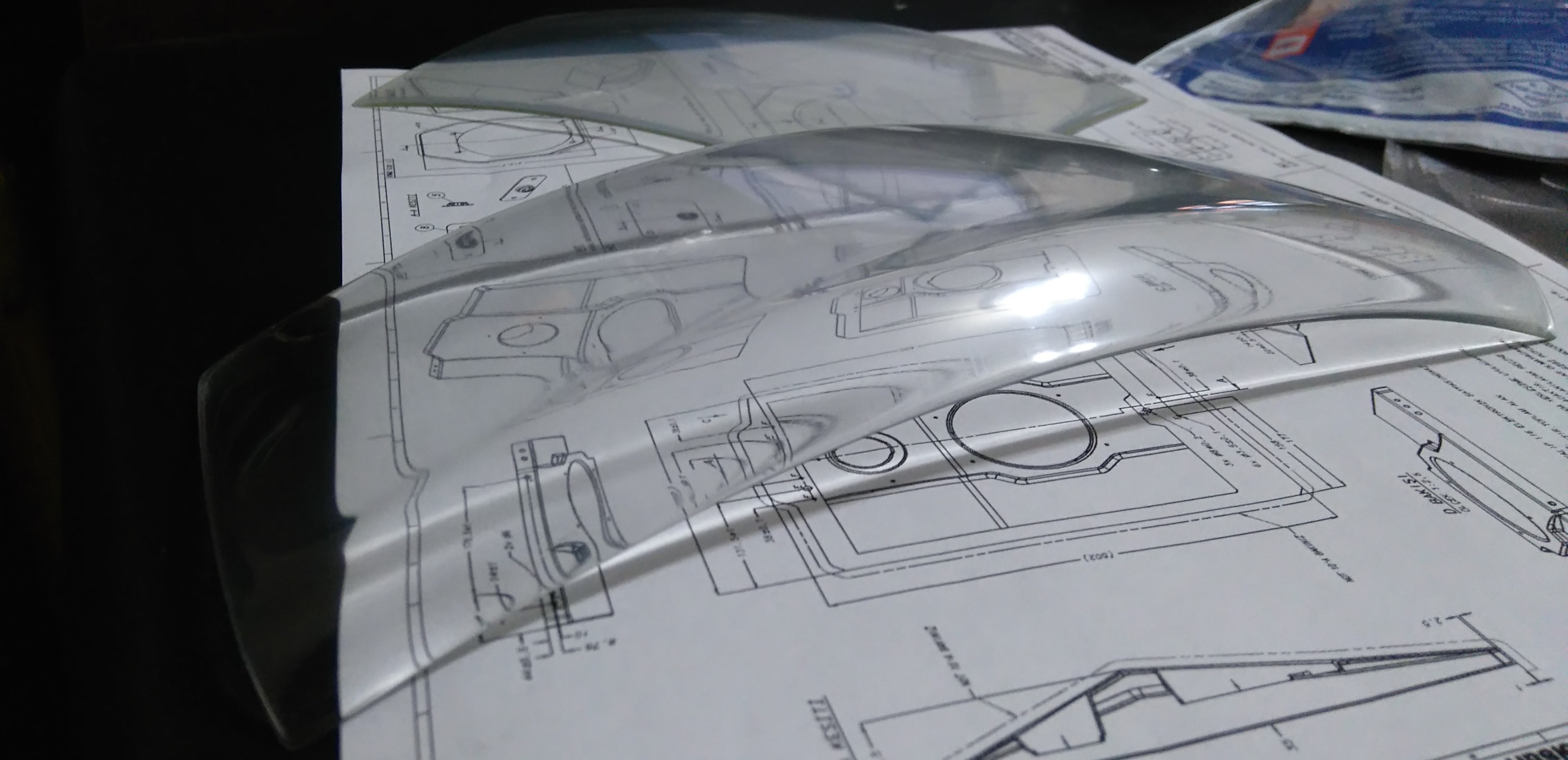

Transparent prototype production is the most difficult and time-consuming one among prototype production methods. When we check today’s prototyping technologies, unfortunately there is no machine capable of producing 100% transparent models yet. This is why we developed our own methods in order to meet the demands of industry, and created a system for producing transparent prototypes.

The biggest problem in transparent prototype making is post process applied after production. As the requested models have a transparency level as glass, even the smallest scratch on the surface affects visual quality. Thanks to our experience and our organized, technical and meticulous work, we are able to conduct 100% transparent prototype production.

If requested, transparent prototypes can also be coated with a transparent paint. Big parts can be produced as disassembled and glued together with transparent filling adhesive if necessary, which maintains visual quality.

Transparent prototypes can be divided into two groups: aesthetic (visual) and functional.

We mostly work in the following areas: